ABOUT THE EVENT

More than 40.000 hot runner systems, 21.280 sqm of facilities, 10 years experience in China.

For HRSflow China, 2018 is a special year: 10 years ago, our manufacturing plant was opened to closely support our Asian customers.

Join us to celebrate our 10th Anniversary!

An unmissable opportunity to come and visit our renovated facility equipped with cutting-edge technologies for Asian Markets.

Main Partners:

WHY ATTEND?

- DISCOVER the latest trends of the Automotive Market in China and the future developments

- LEARN more from executive level professionals of the plastics industry

- VISIT HRSflow renovated facility and explore our

cutting-edge hot runner technologies - EXPERIENCE FLEXflow hot runner technology: live molding demonstration on site!

- CELEBRATE with us HRSflow’s 10th Anniversary in China accompanied by good food and drink

AGENDA

Welcome & Registration

> 1.00 pm Registration & Networking

> 2.00 pm Welcome to the Technical Open House - HRSflow & Krauss Maffei

________________________________________________________________________________________________________________

Main Conference

> 2.10 pm Corporate Presentation of HRSflow China – Technology and Support for Today and Tomorrow - Osvaldo Carloni, INglass Asia President

> 2.20 pm Latest Trends in Injection Molding Technologies: Manufacturing Solutions for the New Automotive Industry - Max Wang, KraussMaffei China IMM Key Account Director

> 2.40 pm Future of the Automotive Market in China & Trends in Asia including Electromobility - Jochen Siebert, JSC Automotive Managing Director

> 3.00 pm Trends in Automotive Plastics for Lightweight Applications - Paul He, SABIC Sr. Business Development Manager, Automotive Marketing

> 3.20 pm Sharing our Expertise in Technology Innovation for Automotive Applications - Ricky Yang, Piovan Regional Sales Head for East China

> 3.40 pm Coffee Break

________________________________________________________________________________________________________________

Company Tour & Live Demo

> 4.00-6.00 pm

Company tour: visit our renovated facility and get a behind-the-scenes view of our production line.

FLEXflow Presentation: discover the benefits our servo driven valve gate system for class “A” surface finish.

FLEXflow Live Molding Demonstration: experience the live demo of a front Chrome Grille. Innovative solutions for family molds.

________________________________________________________________________________________________________________

Dinner & Networking Opportunity

> From 6.00 pm

Celebrate with us our 10th Anniversary in relaxed atmosphere, accompanied by good food and drink.

SPEAKERS

OSVALDO CARLONI, INglass Asia President

Corporate Presentation of HRSflow China – Technology and Support for Today and Tomorrow

Car Programs launch to market is more and more time compressed. HRSflow can promptly respond to the market needs thanks to a global network and to skilled local teams. Our web-based tools can provide efficient transfer of design data along with shorter manufacturing lead times and rapid service support. The presentation will also provide insight into the new advancements in valve pin control with a special focus on FLEXflow technology: innovative solution to provide A - class moulded parts in a single shot within a family mold layout. This is truly "A First" in injection molding processing.

MAX WANG, KraussMaffei China IMM Key Account Director

Latest Trends in Injection Molding Technologies: Manufacturing Solutions for the New Automotive Industry

The KraussMaffei product brand is internationally recognized for its groundbreaking, multitechnology system and process solutions for injection and reaction molding technology and factory automation. With Plastics 4.0 KraussMaffei offers a bundle of cutting-edge digital solutions to the industry. The results are higher productivity, increase of quality and flexibility for the automotive industry.

JOCHEN SIEBERT, JSC Automotive, Managing Director

Future of the Automotive Market in China and Trends in Asia including Electromobility

The economic situation in China and regulatory changes have led to a different situation for the OEMs. In his speech Jochen Siebert will focus on the drivers of the trends that influence the future of the biggest car market in the world. Besides he shows what new opportunities the ASEAN region offers to suppliers.

PAUL HE, SABIC Sr. Business Development Manager, Automotive Marketing

Trends in Automotive Plastics for Lightweight Applications

Global Automotive industry is moving towards lower fuel consumption and stricter CO2 emission standard. OEMs take several different solutions including light weight design to meet the increasing requirements. As one of the leading companies in chemical industry, SABIC offers a series of innovative light weight solutions for automotive customers which were developed based on our wide material portfolio and deep automotive application experience.

RICKY YANG, Piovan Regional Sales Head for East China

Sharing our Expertise in Technology Innovation for Automotive Applications

Focus on innovation has always been one of the key factors driving the growth of the Piovan group. The processes employed by the plastics industry in the automotive sector are the outcome of a vast array of technologies that evolve at a high pace. Our presentation will give the audience an overview of the technological advancements in the plastics processing, targeting energy efficiency and will show a case of improved operating performance of the system resulting in highly qualitative characteristics of the end products.

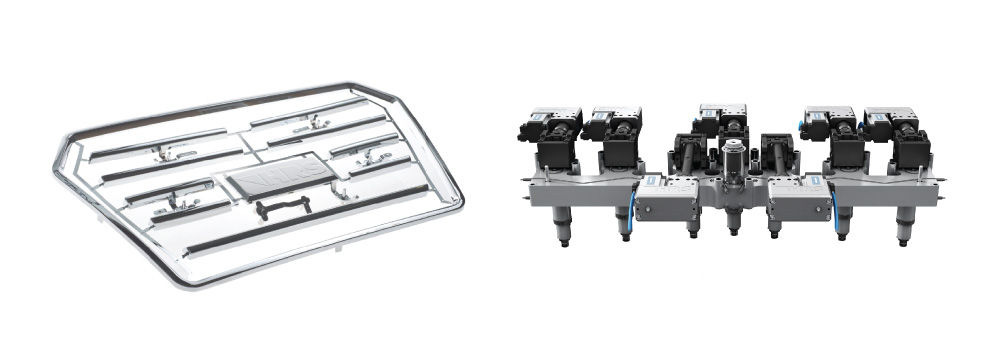

FLEXflow LIVE DEMO

Are you ready to experience our FLEXflow Technology for premium automotive parts?

The innovative, servo-driven valve gate system for accurate, easy to operate and flexible control of pressures and flow rates.

Main Benefits

-

Breakthrough technology for family molds

-

Achievable superior surface quality results

-

Molded parts to chrome-plated without additional preparation

Technical Features

- Live molding demonstration on a KraussMaffei GX 650

- Nominal part dimensions: 22.8 x 13.0 in (580 x 330 mm)

- Nominal part weight: 297 g

- Nominal part thickness: different wall thickness, from 0.08 to 0.12 in (from 2 to 3 mm)

- System Type: 10 Conical Valve Gate Ma series

- Cascade system: 10 FLEXflow drops, servo driven valve gate

- Molding material: SABIC CYCOLOY

KRAUSS MAFFEI GX 650 ON SITE

Main Benefits

-

Powerful

-

User-friendly

-

Value proven

Technical Features

-

KraussMaffei GX 650

CONTACTS

Location

Location

INglass Tooling & Hot Runner

Manufacturing (China) Co. Ltd

Production Plant Hangzhou

Econ. & Tech. Devel. Zone No. 385,

Road No. 18 XIASHA

Ind. Zone, Zhejiang, 310018

Email

Email

Our events staff

are at your disposal:

asia.events@hrsflow.com

Telephone

Telephone

For any questions please contact:

+86 571 86686999

Grace Huang / Bill Hu