CHALLENGING APPLICATIONS AT FAKUMA 2018:

Visit our booth and see for yourself the benefits of our servo driven valve gate technology and much more.

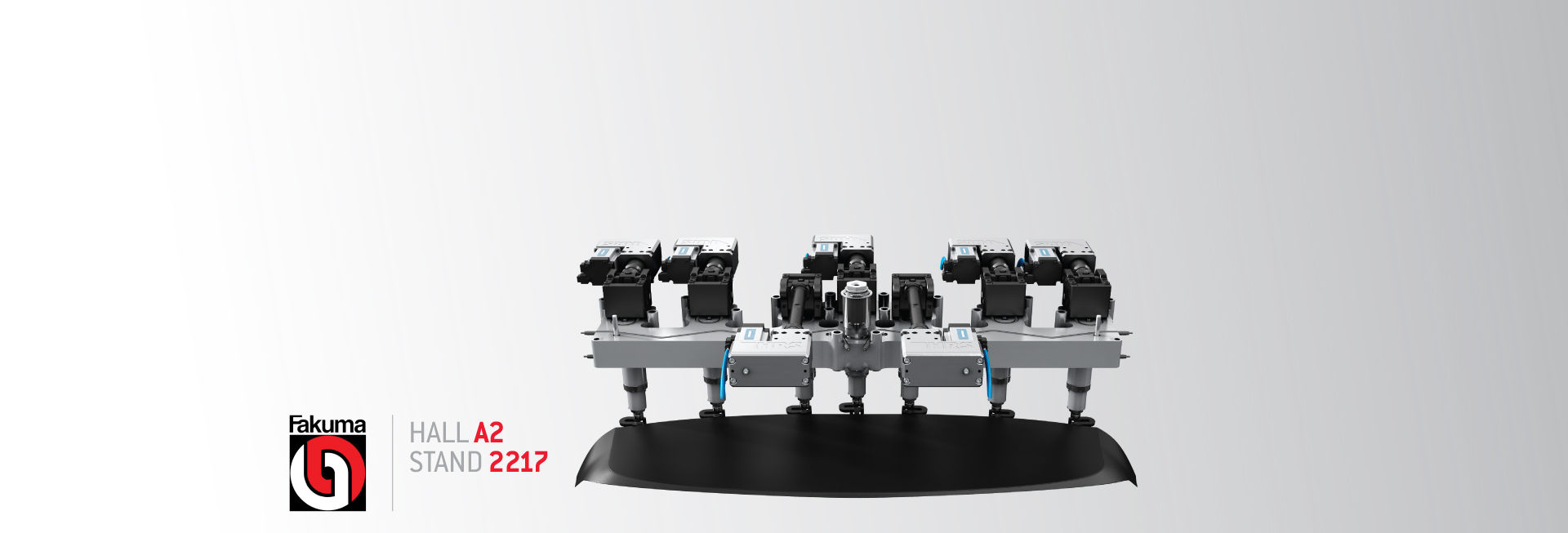

Challenging solutions for family molds

Application: Automotive inner door trim

Material: PP

Hot runner system: 8 FLEXflow Servo Driven Valve Gate

In cooperation with: INCOS, HRSflow

Special features: The three high-quality visible parts of the inner door trim are characterized by different thicknesses and different volumes. The parts can be produced together in a single shot or one by one in a sequential order. The precise and responsive FLEXflow Family Technology allows to prevent unaesthetic sink marks as well as flashes on the molded parts. Hot runner design optimized for color-change, overall injection pressure reduction, clamping force reduction.

Lightweight under-hood application

Application: lightweight engine cover

Material: PA6.6 GF 30%

Hot runner system: 2 FLEX¬ow drops, servo driven valve gate

In cooperation with: Akro-plastic, Eschmann, GK CONCEPT, HRSflow, Lyondell Basell, Yizumi

Special features: FLEXflow One, in Mould Graining technology, combined with back injection aluminium foil and physical foaming. The part is characterized by a great dimensional stability. Furthermore, our FLEXflow One system ensures maximum control of the melt flow and warpage.

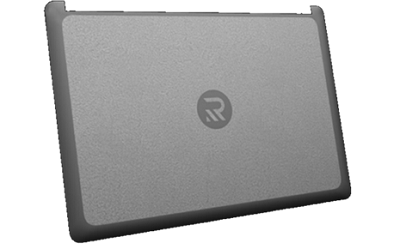

Special surface effect produced in one shot

Application: Laptop A-Cover 14”

Material: PC GF50%

Hot runner system: 5 FLEXfow drops, servo driven valve gate

In cooperation with: FLEX, HRSflow, KraussMaffei, Roctool, Sabic

Special features: The result is an exciting surface effect produced in one shot: with 1.5 mm thickness, this application is characterized by the combination of a high gloss and a low gloss finishing. In addition, thanks to this solution, production scraps and cycle time are considerably reduced. The cycle time is lowered to 1 minute in order to match industry needs.

Innovative technology for houseware

Application: collapsible bath box

Material: PP, TPE

Hot runner system: (PP injection phase) 10 drops, HRS Line Ma Series - (TPE injection phase) 4 drops, HRS Line Pa Series

Special features: suitable for color change, high structural performance on joint areas, overmolding.

The collapsible bath box application is characterized by a high structural result of the whole part and an optimal stability on the joint areas even with two different molding materials. Suitable for color change, ideal solution to fill different volume cavities with PP, excellent aesthetic result.

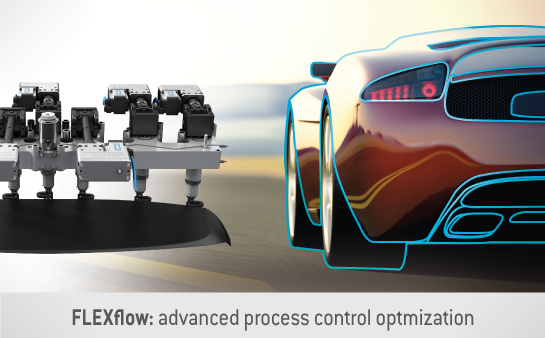

FLEXflow FAMILY: CHALLENGE YOUR EXPECTATIONS

Electric, efficient, evolved.

FLEXflow Family includes the electrically driven valve gate systems, FLEXflow and FLEXflow One.

How will you drive perfection?

The electrical technology is designed for the independent adjustment of each valve pin with precise control of stroke, velocity and force during opening and closing phases.

This solution assures accurate, easy to operate, flexible control of pressure and flow rates at each individual gate during the injection process.

Aesthetic benefits

- Quality improvements for Class “A” large, surfaces, chromed surfaces

- Warp reduction

- Optimal flow balancing

- Wall thickness reduction

Cost effective

- Clamping force reduction

- Scrap reduction

- High process repeatability

- Mold deflection reduction

- Successful family mold operation

Operational benefits

- Reduced maintenance

- Wider process window

- Clean operation

- Easy to use

YOUR RELIABLE PARTNER FOR A WIDE RANGE OF APPLICATIONS

Domestic appliances

Houseware

Technical applications

Logistics & Environmental

Automotive exterior

Automotive interior

Automotive lighting

Under-the-hood

FOR ALL YOUR NEEDS, OUR EXCEPTIONAL SUPPORT

100% thermal analysis simulations

Specific thermal analysis simulations are provided on 100% of our systems in order to optimize final performance and to ensure a uniform thermal distribution.

Identical world wide standard

Our processes, design, production and quality are identical wherever they are located: from our manufacturing facilities in Italy to Hangzhou-China, and Grand Rapids, Michigan USA.

Our service 4.0: pre and after sales efficiency

We ensure a prompt response from our web-based service platform, optimized stocks of spare parts and our service tools such as Troubleshooting and e-TS (Electronic Tool Standard).

Automated production and process integration

We have invested significantly in the automation of the production of our products, not only increasing our capacity, but more importantly to ensure performance consistency and reliability.