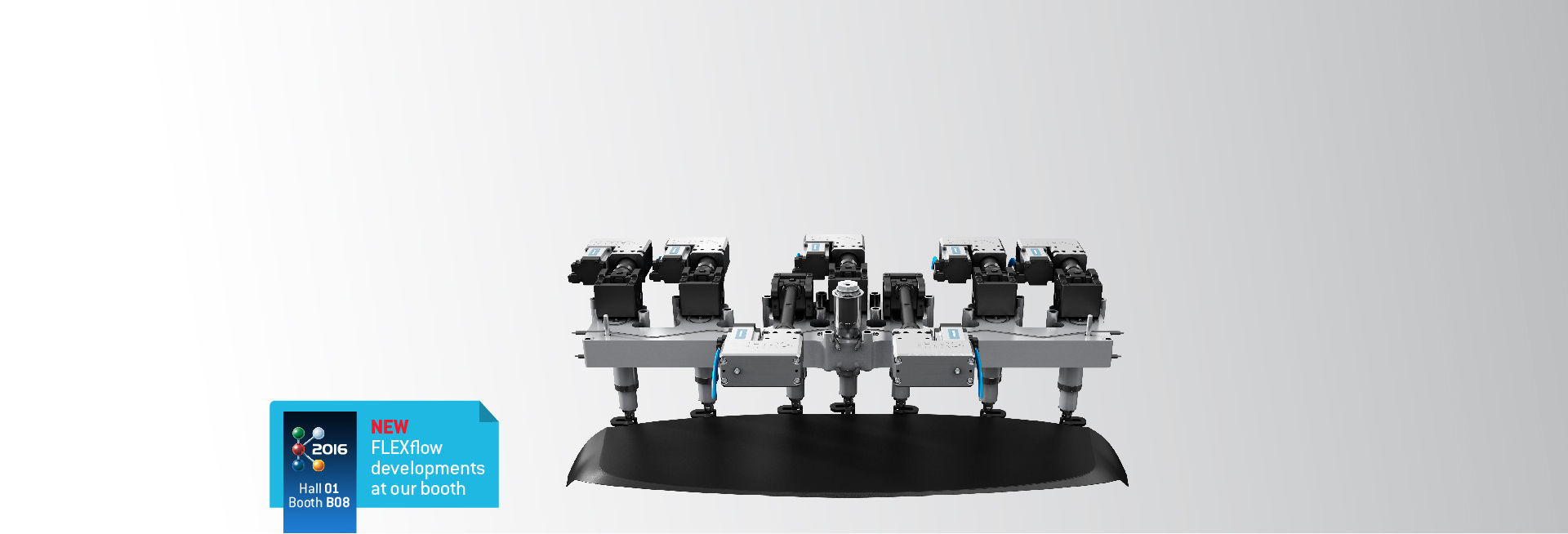

FLEXFLOW LIVE MOLDING DEMONSTRATIONS AT K 2016

flexflow molding APPLICATIONS AT OUR PARTNER BOOTHs

FLEXflow Benefits

FLEXflow is a servo-driven valve gate that assures independent control of each valve gate by precisely adjusting position, acceleration, velocity and stroke of the valve pin.

> Surface quality improvement

> Clamping force reduction

> High process repeatability and reliability

> Flow rate and pressure control

hrsflow expertise for your Automotive applications

Interior

We reach the highest quality standards for the demands of the automotive industry. Our technology ensures the best touch and feel experience of the interior parts.

Exterior

We develop turnkey hot runner solutions for large injection moulded parts for class “A” surface finishes. Systems are completely pre-wired and pre-assembled.

Lighting

We offer specific hot runner designs dedicated to the strict requirements of front and rear lenses to meet the extremely high quality needs of this challenging market.

Under-the-hood

Our systems are designed with wear resistant components for processing of high performance materials and they withstand extreme operating temperatures.

FOR ALL YOUR NEEDS HRSflow EXCEPTIONAL SUPPORT

100% thermal analysis simulations

Specific thermal analysis simulations are provided on 100% of our systems in order to optimize final performance and to ensure a uniform thermal distribution.

Identical world wide standard

Our processes, design, production and quality are identical wherever they are located: from our manufacturing facilities in Italy to Hangzhou-China, and Grand Rapids, Michigan USA.

Our service 4.0: pre and after sales efficiency

We ensure a prompt response from our web-based service platform, optimised stocks of spare parts and our service tools such as Troubleshooting and e-TS (Electronic Tool Standard).

Automated production and process integration

We have invested significantly in the automation of the production of our products, not only increasing our capacity, but more importantly to ensure performance consistency and reliability.

OUR GOAL IS YOUR SATISFACTION

We are engaged in the ambitious project to be the worldwide leader in the quality and service for the products we provide throughout the entire sales process: pre and after sales.

We refer to this goal as “QS1”: Quality and Service first! We have implemented important values of the 4.0 regulations such as the constant monitoring of KPI, and dynamic organizational structure in the KPO department ensuring a LEAN organization.

We look forward to being a part of our customers success.