LIVE DEMO AT OUR PARTNERS' BOOTHS

CUTTING EDGE PARTNERSHIPS FOR BOLD APPLICATIONS IN ALL INDUSTRIES

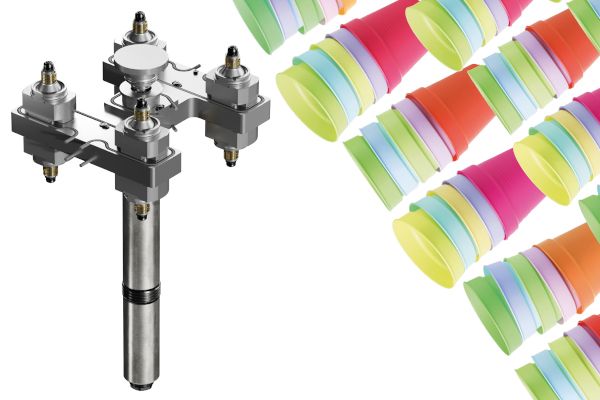

THIN-WALLED 150ML IML YOGURT CUP

Netstal Hall 15, Booth D24

Highlights

> Xp nozzle series engineered for thin wall packaging

> Processing of a certified renewable SABIC® PP polymer

> Reliable productivity at the lowest cost per unit

> Ambitious cycle times (3.9 s)

> NextCycle IML™ label for package recycling

Project partners: Netstal, IML Solutions, MCC Verstraete,Sabic, Oerlikon HRSflow.

ECO-FRIENDLY FRUIT BOX

Haitian - Hall 15, Booth A57

Highlights

> Hot runner configuration designed for recycled PE filled with recycled Tetra Pak aluminum foil

> Fully electric solution for the maximum energy saving

> High process repeatability

Project Partners: Haitian, Mundimold, Tetra Pak, APS, Oerlikon HRSflow.

MULti-component tool case

Arburg - Hall 13, Booth A/B13

Highlights

> Two covers from a PC/ABS blend in a family mold

> Hot runner solutions engineered to process PET RECOPOUND® by KURZ

> High structural result of the final part

Project partners: Arburg, Hofmann, LEONHARD KURZ, Oerlikon HRSflow.

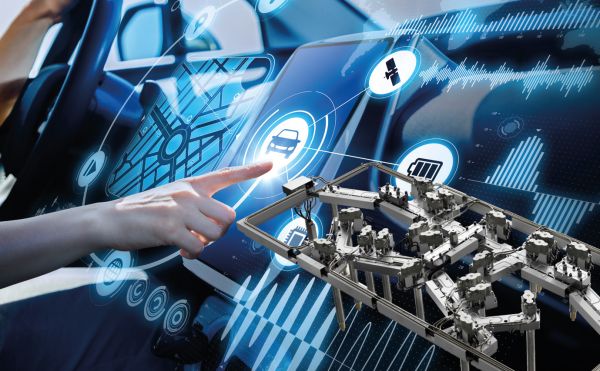

2K REAR PANEL

ENGEL - Hall 15, Booth C58

Highlights

> PC+ABS frame overmolded with PMMA or alternative PC

> Decorated with a capacitive and aesthetic film directly in the mold

> Rheological analysis to meet the complex requirements

Project Partners: ENGEL, Schöfer, LEONHARD KURZ, Röhm, Oerlikon HRSflow.

3 COMPONENT COFFEE-TO-GO CUP

Wittmann-Battenfeld - Hall 15, Booth C06

Highlights

> Hot runner solution optimized to process the 100% recyclable PP Bornewables™

> The inner clear optic cup is over-molded with an insulated shell

> Insulating effect obtained by foaming the melt through the Cellmould® technology

Project partners: Wittmann Battenfeld, Haidlmair, Borealis, Oerlikon HRSflow.

2K Irrigation connector

Billion Hall 15, Booth B24

Highlights

> First injection: optimized hot runner system to process styrenic compounds

Open gate tip designed to fit a narrow gate area

> Second injection: optimized hot runner system to process elastomer compounds.

Valve gate hydraulic activation cylinder designed for narrow pitch

Project partners: Billion, Groupe Pernoud, Actemium, Sepro Group, Resinex, Lifocolor and DeViris, Oerlikon HRSflow.

HIGH GLOSS B PILLAR

Tederic Hall 15, Booth D40

Highlights

> 2K hot runner system

> First phase: 2 drops conical valve gate hydraulic system combined with ICM Technology optimized to proces PMMA

> Second phase: 6 drops hot runner system optimized to process ABS material

> Perfect appearance of the component thanks to a gentle, low-stress injection

Project partners: Tederic, Yuyao Skymold, Piovan and Technotrans Solutions GmbH, Oerlikon HRSflow.

MJA DOOR PANEL

Only on display!

Highlights

> Different textures in the same cavity

> Foaming performance and thin-wall design obtained thanks to FLEXflow valve gate control

> 23% lighter compared to the traditional injection molding

> Energy-efficient solution promoting a lower demand for IMM clamping force

> High process repeatability

Project partners: ENGEL, Forvia/Faurecia, Eschmann Textures, APM, Oerlikon HRSflow.

BOOTH HIGHLIGHTS

NEW SOLUTIONS FOR LOW SHOT WEIGHTS AND CAPS&CLOSURES

The main benefits of our multicavity line include: fast color change, short cycle times, processing of PCR compounds and biopolymers, design flexibility, fast start-up production, high process and product repeatability. On display at our booth, the new Vf nozzle series specifically engineered for the market of Caps&Closures. Equipped with a special nozzle tip, it ensures fast cycle times and an optimal thermal distribution at the gate area reducing the mold cavity surface wear even with high production volumes.

NEW XP SERIES OF VALVE GATE NOZZLES FOR THIN-WALL INJECTION MOLDING

Designed to withstand high filling pressures, up to 2200 bar, it enables fast cycle times without compromise on quality. An innovative, patent-pending solution for stack systems in thin-wall injection molding has been developed. Assembly operations are extremely simplified thanks to a plug-and-play installation despite of the compactness of the whole system.

HOT RUNNER SOLUTIONS FOR FUTURISTIC AUTOMOTIVE SMART SURFACES

Running live at ENGEL booth, the injection molding of a smart 2K Rear Panel composed by a PC/ABS frame overmolded with PMMA or alternative PC. The part will be finally decorated with a capacitive and aesthetic film directly in the mold for an innovative result. Among the hot runner solutions provided by Oerlikon HRSflow for the IMD (In-Mold-Decoration) and FIM (Film Insert Molding) technology, the most revolutionary one is certainly FLEXflow. With its servo-electric needle positioning, it enables precisely controlled overmolding of the sensitive electronic components with high-quality surfaces at the same time.

EXPERT TALKS ON STAGE!

Embracing digitization and sustainability means leading your company into the future.

How will sustainability change the sectors of medical, electronics, packaging, beverage & home? How will our hot runner solutions support the process of digitization? These questions and more will be discussed throughout the Live Presentations at our booth (Hall 1, Booth D 10). Join us!

SUSTAINABILITY

Market Trends and Oerlikon HRSflow commitment for a more sustainable Packaging.

Sustainability in packaging is a megatrend shaping the packaging industry of the future in terms of regulations, design, materials and production processes.

Oerlikon HRSflow have developed innovative technical solutions to make easier the key objective to reduce packaging impact on the environment.

Demo molds running at Kshow will be illustrated as practical examples of our commitment to more green solutions.

DIGITIZATION

On the way to the digital process twin. A closed loop workflow to bring your filling simulation and injection molding process to the next level.

Borealis Polyolefine GmbH, ENGEL Austria GmbH and Oerlikon HRSflow have demonstrated in a joint project how close simulation can be to reality today. Discover how to redesign the workflow to create and transfer your filling simulation to the injection moulding machine. The project was illustrated with a real component: a car door module.

procesS capabilities

Enhanced process capabilities & significant quality improvement through servo-driven hot runner system.

The servo-driven valve gate system allows to control the volume flow at each individual nozzle resulting in part quality improvement with regard to surface effects, component distortion and stresses. Thanks to the process flexibility, family molds with different shot weights of the individual parts can be produced series-safely. In addition, the system offers several benefits in back injection technology for decorative materials and capacitive films. Practical examples will be used to explain the advantages.

Speaker

Alessandra Bosco, Head of Business Development - Packaging & Medical at Oerlikon HRSflow

Speakers

Markus Kralicek, Business Development Manager at Borealis, Michael Fischer, Head of Business Development Automotive Technologies at ENGEL, and Stephan Berz, Vice President Sales at Oerlikon HRSflow and General Manager DACH

Speaker

Stephan Berz, Vice President Sales Oerlikon HRSflow and General Manager DACH

When

Thursday, 20.10.2022 at 11.00 am

Monday, 24.10.2022 at 4.00 pm

When

Thursday, 20.10.2022 at 4.35 pm

Tuesday, 25.10.2022 at 4.35 pm

When

Friday, 21.10. 2022 at 11.00 am

Monday, 24.10 2022 at 11.00 am

ABout Oerlikon HRSflow

Oerlikon HRSflow - part of the Swiss Technology group Oerlikon - specializes in development and production of advanced hot runner systems for a wide range of applications in the plastic injection molding industry: automotive, logistics&environmental, domestic appliances, mobility, houseware, gardening, technical applications, medical, beverage&home, thin wall packaging, beauty&personal care markets.

Our highly qualified technical team supports our customers in all stages, from the initial design and simulation through the construction of the hot runner system including try-out support.

Oerlikon HRSflow manufactures hot runner systems in Europe (Italy), Asia (Hangzhou) and at Byron Center, Michigan, United States. The production performance is the same worldwide, because the factories boast identical equipment and standard processes. The Company provides global support for its products acting through more than 50 sales/service centers worldwide with a 24/7 technical service.